Technical Info

Manufacturing and Supplying of S.S.Fasteners

ASTM 193/194/A320 Specifications

ASTM 193 GRADES

| B7 | Alloy steel, AISI 4140/4142 quenched and tempered |

| B8 | Class 1 Stainless steel, AISI 304, carbide solution treated. |

| B8M | Class 1 Stainless steel, AISI 316, carbide solution treated. |

| B8 | Class 2 Stainless steel, AISI 304, carbide solution treated, strain hardened |

| B8M | Class 2 Stainless steel, AISI 316, carbide solution treated, strain hardened |

MECHANICAL PROPERTIES

| Grade | Size | Tensile ksi, min | Yield, ksi, min | Elong, %, min | RA % min |

| B7 | Up to 2-1/2 | 125 | 105 | 16 | 50 |

| 2-5/8 - 4 | 115 | 95 | 16 | 50 | |

| 4-1/8 - 7 | 100 | 75 | 18 | 50 | |

| B8 Class 1 | All | 75 | 30 | 30 | 50 |

| B8M Class 1 | All | 75 | 30 | 30 | 50 |

| B8 Class 2 | Up to 3/4 | 125 | 100 | 12 | 35 |

| 7/8 - 1 | 115 | 80 | 15 | 35 | |

| 1-1/8 - 1-1/4 | 105 | 65 | 20 | 35 | |

| 1-3/8 - 1-1/2 | 100 | 50 | 28 | 45 | |

| B8M Class 2 | Up to 3/4 | 110 | 95 | 15 | 45 |

| 7/8 - 1 | 100 | 80 | 20 | 45 | |

| 1-1/8 - 1-1/4 | 95 | 65 | 25 | 45 | |

| 1-3/8 - 1-1/2 | 90 | 50 | 30 | 45 |

ASTM A 194 GRADE

Mechanical Properties

Grade Identification Markings

| Grade Identification Marking5 | Specification | Material | Nominal Size, In. | Tempering Temp. °F | Proof Load Stress, ksi | Hardness Rockwell | See Note | |

| Min | Max | |||||||

| 2 | ASTM A194 Grade 2 | Medium Carbon Steel | 1/4 - 4 | 1000 | 150 | 159 | 352 | 1,2,3 |

| 2H | ASTM A194 Grade 2H | Medium Carbon Steel, Quenched and Tempered | 1/4 - 4 | 1000 | 175 | C24 | C38 | 1,2 |

| 2HM | ASTM A194 Grade 2HM | Medium Carbon Steel, Quenched and Tempered | 1/4 - 4 | 1000 | 150 | 159 | 237 | 1,2,3 |

| 4 | ASTM A194 Grade 4 | Medium Carbon Alloy Steel, Quenched and Tempered | 1/4 - 4 | 1100 | 175 | C24 | C38 | 1,2 |

| 7 | ASTM A194 Grade 7 | Medium Carbon Alloy Steel, Quenched and Tempered | 1/4 - 4 | 1100 | 175 | C24 | C38 | 1,2 |

| 7M | ASTM A194 Grade 7M | Medium Carbon Alloy Steel, Quenched and Tempered | 1/4 - 4 | 1100 | 150 | 159 | 237 | 1,2,3 |

| 8 | ASTM A194 Grade 8 | Stainless AISI 304 | 1/4 - 4 | - | 80 | 126 | 300 | 4 |

| 8M | ASTM A194 Grade 8M | Stainless AISI 316 | 1/4 - 4 | - | 80 | 126 | 300 | 4 |

ASTM 194 NUT DIMENSIONS

| Nominal Size | F | C | H | Weight | |||||

| Width Across Flats | Width Across Corners | Thickness | Per Nut | ||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 | 0.03 |

| 1/2 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 31/64 | 0.504 | 0.464 | 0.07 |

| 5/8 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 | 0.12 |

| 3/4 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.710 | 0.20 |

| 7/8 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 55/64 | 0.885 | 0.833 | 0.30 |

| 1 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 | 0.43 |

| 1-1/8 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1-7/64 | 1.139 | 1.079 | 0.59 |

| 1-1/4 | 2 | 2.000 | 1.938 | 2.309 | 2.209 | 1-7/32 | 1.251 | 1.187 | 0.79 |

| 1-3/8 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1-11/32 | 1.378 | 1.310 | 1.02 |

| 1-1/2 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1-15/32 | 1.505 | 1.433 | 1.31 |

| 1-5/8 | 2-9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1-19/32 | 1.632 | 1.556 | 1.62 |

| 1-3/4 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-23/32 | 1.759 | 1.679 | 2.04 |

| 1-7/8 | 2-15/16 | 2.938 | 2.844 | 3.392 | 3.242 | 1-27/32 | 1.886 | 1.802 | 2.41 |

| 2 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-31/32 | 2.013 | 1.925 | 2.99 |

| 2-1/4 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 2-13/64 | 2.251 | 2.155 | 4.19 |

| 2-1/2 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 2-29/64 | 2.505 | 2.401 | 5.64 |

| 2-3/4 | 4-1/4 | 4.250 | 4.112 | 4.907 | 4.688 | 2-45/64 | 2.759 | 2.647 | 7.38 |

| 3 | 4-5/8 | 4.625 | 4.475 | 5.340 | 5.102 | 2-61/64 | 3.013 | 2.893 | 9.50 |

| 3-1/4 | 5 | 5.000 | 4.838 | 5.774 | 5.515 | 3-3/16 | 3.252 | 3.124 | 11.94 |

| 3-1/2 | 5-3/8 | 5.375 | 5.200 | 6.207 | 5.928 | 3-7/16 | 3.506 | 3.370 | 15.26 |

| 3-3/4 | 5-3/4 | 5.750 | 5.562 | 6.640 | 6.341 | 3-11/16 | 3.760 | 3.616 | 18.12 |

| 4 | 6-1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3-15/16 | 4.014 | 3.862 | 21.80 |

| Dimensions per ASME B18.2.2 1987 (1999) | |||||||||

ASTM A320 Grades

- L7 Alloy steel, AISI 4140/4142 Quenched and tempered

- L43 Alloy steel, AISI 4340 Quenched and tempered

- B8 Class 1 Stainless steel, AISI 304, carbide solution treated

- B8M Class 1 Stainless steel, AISI 316, carbide solution treated

- B8 Class 2 Stainless steel, AISI 304, carbide solution treated, strain hardened

- B8M Class 2 Stainless steel, AISI 316, carbide solution treated, strain hardened

Mechanical Properties

| Grade | Size | Tensile, ksi, min |

Yield, ksi, min |

Charpy Impact 20-ft-lbf @ temp |

Elong, %, min |

RA, %, min |

| L7 | Up to 21/2 | 125 | 105 | -150° F | 16 | 50 |

| L43 | Up to 4 | 125 | 105 | -150° F | 16 | 50 |

| B8 Class 1 |

All | 75 | 30 | N/A | 30 | 50 |

| B8M Class 1 |

All | 75 | 30 | N/A | 30 | 50 |

| B8 Class 2 |

Up to 3/4 | 125 | 100 | N/A | 12 | 35 |

| 7/8 - 1 | 115 | 80 | N/A | 15 | 35 | |

| 11/8 - 11/4 | 105 | 65 | N/A | 20 | 35 | |

| 13/8 - 11/2 | 100 | 50 | N/A | 28 | 45 | |

| B8M Class 2 |

Up to 3/4 | 110 | 95 | N/A | 15 | 45 |

| 7/8 - 1 | 100 | 80 | N/A | 20 | 45 | |

| 11/8 - 11/4 | 95 | 65 | N/A | 25 | 45 | |

| 13/8 - 11/2 | 90 | 50 | N/A | 30 | 45 |

Recommended Nuts and Washers

| Grade | Nuts | Washers |

| L7 | A194 Grade 4 or 7 | F436 |

| L43 | A194 Grade 4 or 7 | F436 |

| B8 Class 1 | A194 Grade 8 | SS304 |

| B8M Class 1 | A194 Grade 8M | SS316 |

| B8 Class 2 | A194 Grade 8, strain hardened | SS304 |

| B8M Class 2 | A194 Grade 8M, strain hardened | SS316 |

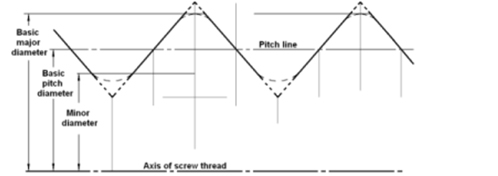

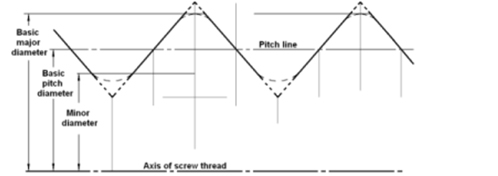

Standard Thread Pitches

| Coarse Thread Series - UNC | Fine Thread Series - UNF | 8-Thread Series - 8UN | |||||||||

| Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area | Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area | Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area |

| In. | Sq in. | Sq in. | In. | Sq in. | Sq in. | In. | Sq in. | Sq in. | |||

| -- -- | -- | -- | -- | 0 - 80 | 0.0519 | 0.00151 | 0.00180 | -- -- | -- | -- | -- |

| 1 - 64 | 0.0629 | 0.00218 | 0.00263 | 1 - 72 | 0.0640 | 0.00237 | 0.00278 | ||||

| 2 - 56 | 0.0744 | 0.00310 | 0.00370 | 2 - 64 | 0.0759 | 0.00339 | 0.00394 | ||||

| 3 - 48 | 0.0855 | 0.00406 | 0.00487 | 3 - 56 | 0.0874 | 0.00451 | 0.00523 | ||||

| 4 - 40 | 0.0958 | 0.00496 | 0.00604 | 4 - 48 | 0.0985 | 0.00566 | 0.00661 | -- -- | -- | -- | -- |

| 5 - 40 | 0.1088 | 0.00672 | 0.00796 | 5 - 44 | 0.1102 | 0.00716 | 0.00830 | ||||

| 6 - 32 | 0.1177 | 0.00745 | 0.00909 | 6 - 40 | 0.1218 | 0.00874 | 0.01015 | ||||

| 8 - 32 | 0.1437 | 0.01196 | 0.0140 | 8 - 36 | 0.1460 | 0.01285 | 0.01474 | ||||

| 10 - 24 | 0.1629 | 0.01450 | 0.0175 | 10 - 32 | 0.1697 | 0.0175 | 0.0200 | -- -- | -- | -- | -- |

| 12 - 24 | 0.1889 | 0.0206 | 0.0242 | 12 - 28 | 0.1928 | 0.0226 | 0.0258 | -- -- | -- | -- | -- |

| 1/4 - 20 | 0.2175 | 0.0269 | 0.0318 | 1/4 - 28 | 0.2268 | 0.0326 | 0.0364 | -- -- | -- | -- | -- |

| 5/16 - 18 | 0.2764 | 0.0454 | 0.0524 | 5/16 - 24 | 0.2854 | 0.0524 | 0.0580 | -- -- | -- | -- | -- |

| 3/8 - 16 | 0.3344 | 0.0678 | 0.0775 | 3/8 - 24 | 0.3479 | 0.0809 | 0.0878 | -- -- | -- | -- | -- |

| 7/16 - 14 | 0.3911 | 0.0933 | 0.1063 | 7/16 - 20 | 0.4050 | 0.1090 | 0.1187 | -- -- | -- | -- | -- |

| 1/2 - 13 | 0.4500 | 0.1257 | 0.1419 | 1/2 - 20 | 0.4675 | 0.1486 | 0.1599 | -- -- | -- | -- | -- |

| 9/16 - 12 | 0.5084 | 0.162 | 0.182 | 9/16 - 18 | 0.5264 | 0.189 | 0.203 | -- -- | -- | -- | -- |

| 5/8 - 11 | 0.5660 | 0.202 | 0.226 | 5/8 - 18 | 0.5889 | 0.240 | 0.256 | -- -- | -- | -- | -- |

| 3/4 - 10 | 0.6850 | 0.302 | 0.334 | 3/4 - 16 | 0.7094 | 0.351 | 0.373 | -- -- | -- | -- | -- |

| 7/8 - 9 | 0.8028 | 0.419 | 0.462 | 7/8 - 14 | 0.8286 | 0.180 | 0.509 | -- -- | -- | -- | -- |

| 1 - 8 | 0.9188 | 0.551 | 0.606 | 1 - 12 | 0.9459 | 0.625 | 0.663 | 1 - 8 | 0.9188 | 0.551 | 0.606 |

| 1-1/8 - 7 | 1.0322 | 0.693 | 0.763 | 1-1/8 - 12 | 1.0709 | 0.812 | 0.856 | 1-1/8 - 8 | 1.0438 | 0.728 | 0.790 |

| 1-1/4 - 7 | 1.1572 | 0.890 | 0.969 | 1-1/4 - 12 | 1.1959 | 1.024 | 1.073 | 1-1/4 - 8 | 1.1688 | 0.929 | 1.000 |

| 1-3/8 - 6 | 1.2667 | 1.054 | 1.155 | 1-3/8 - 12 | 1.3209 | 1.260 | 1.315 | 1-3/8 - 8 | 1.2938 | 1.155 | 1.233 |

| 1-1/2 - 6 | 1.3917 | 1.294 | 1.405 | 1-1/2 - 12 | 1.4459 | 1.521 | 1.581 | 1-1/2 - 8 | 1.4188 | 1.405 | 1.492 |

| -- -- | -- | -- | -- | -- -- | -- | -- | -- | 1-5/8 - 8 | 1.5438 | 1.68 | 1.78 |

| 1-3/4 - 5 | 1.6201 | 1.74 | 1.90 | -- -- | -- | -- | -- | 1-3/4 - 8 | 1.6688 | 1.98 | 2.08 |

| -- -- | -- | -- | -- | -- -- | -- | -- | -- | 1-7/8 - 8 | 1.7938 | 2.30 | 2.41 |

| 2 - 4-1/2 | 1.8557 | 2.30 | 2.50 | -- -- | -- | -- | -- | 2 - 8 | 1.9188 | 2.65 | 2.77 |

| 2-¼ - 4-½ | 2.1057 | 3.02 | 3.25 | -- -- | -- | -- | -- | 2-1/4 - 8 | 2.1688 | 3.42 | 3.56 |

| 2-1/2 - 4 | 2.3376 | 3.72 | 4.00 | -- -- | -- | -- | -- | 2-1/2 - 8 | 2.4188 | 4.29 | 4.44 |

| 2-3/4 - 4 | 2.5876 | 4.62 | 4.93 | -- -- | -- | -- | -- | 2-3/4 - 8 | 2.6688 | 5.26 | 5.43 |

| 3 - 4 | 2.8376 | 5.62 | 5.97 | -- -- | -- | -- | -- | 3 - 8 | 2.9188 | 6.32 | 6.51 |

| 3-1/4 - 4 | 3.0876 | 6.72 | 7.10 | -- -- | -- | -- | -- | 3-1/4 - 8 | 3.1688 | 7.49 | 7.69 |

| 3-1/2 - 4 | 3.3376 | 7.92 | 8.33 | -- -- | -- | -- | -- | 3-1/2 - 8 | 3.4188 | 8.75 | 8.96 |

| 3-3/4 - 4 | 3.5876 | 9.21 | 9.66 | -- -- | -- | -- | -- | 3-3/4 - 8 | 3.6688 | 10.11 | 10.34 |

| 4 - 4 | 3.8376 | 10.61 | 11.08 | -- -- | -- | -- | -- | 4 - 8 | 3.9188 | 11.57 | 11.81 |

Stainless Steel Chemical Composition

| Coarse Thread Series - UNC | Fine Thread Series - UNF | 8-Thread Series - 8UN | |||||||||

| Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area | Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area | Nominal Size and Threads Per In. | Basic Pitch Dia. | Section at Minor Dia. | Tensile Stress Area |

| In. | Sq in. | Sq in. | In. | Sq in. | Sq in. | In. | Sq in. | Sq in. | |||

| -- -- | -- | -- | -- | 0 - 80 | 0.0519 | 0.00151 | 0.00180 | -- -- | -- | -- | -- |

| 1 - 64 | 0.0629 | 0.00218 | 0.00263 | 1 - 72 | 0.0640 | 0.00237 | 0.00278 | ||||

| 2 - 56 | 0.0744 | 0.00310 | 0.00370 | 2 - 64 | 0.0759 | 0.00339 | 0.00394 | ||||

| 3 - 48 | 0.0855 | 0.00406 | 0.00487 | 3 - 56 | 0.0874 | 0.00451 | 0.00523 | ||||

| 4 - 40 | 0.0958 | 0.00496 | 0.00604 | 4 - 48 | 0.0985 | 0.00566 | 0.00661 | -- -- | -- | -- | -- |

| 5 - 40 | 0.1088 | 0.00672 | 0.00796 | 5 - 44 | 0.1102 | 0.00716 | 0.00830 | ||||

| 6 - 32 | 0.1177 | 0.00745 | 0.00909 | 6 - 40 | 0.1218 | 0.00874 | 0.01015 | ||||

| 8 - 32 | 0.1437 | 0.01196 | 0.0140 | 8 - 36 | 0.1460 | 0.01285 | 0.01474 | ||||

| 10 - 24 | 0.1629 | 0.01450 | 0.0175 | 10 - 32 | 0.1697 | 0.0175 | 0.0200 | -- -- | -- | -- | -- |

| 12 - 24 | 0.1889 | 0.0206 | 0.0242 | 12 - 28 | 0.1928 | 0.0226 | 0.0258 | -- -- | -- | -- | -- |

| 1/4 - 20 | 0.2175 | 0.0269 | 0.0318 | 1/4 - 28 | 0.2268 | 0.0326 | 0.0364 | -- -- | -- | -- | -- |

| 5/16 - 18 | 0.2764 | 0.0454 | 0.0524 | 5/16 - 24 | 0.2854 | 0.0524 | 0.0580 | -- -- | -- | -- | -- |

| 3/8 - 16 | 0.3344 | 0.0678 | 0.0775 | 3/8 - 24 | 0.3479 | 0.0809 | 0.0878 | -- -- | -- | -- | -- |

| 7/16 - 14 | 0.3911 | 0.0933 | 0.1063 | 7/16 - 20 | 0.4050 | 0.1090 | 0.1187 | -- -- | -- | -- | -- |

| 1/2 - 13 | 0.4500 | 0.1257 | 0.1419 | 1/2 - 20 | 0.4675 | 0.1486 | 0.1599 | -- -- | -- | -- | -- |

| 9/16 - 12 | 0.5084 | 0.162 | 0.182 | 9/16 - 18 | 0.5264 | 0.189 | 0.203 | -- -- | -- | -- | -- |

| 5/8 - 11 | 0.5660 | 0.202 | 0.226 | 5/8 - 18 | 0.5889 | 0.240 | 0.256 | -- -- | -- | -- | -- |

| 3/4 - 10 | 0.6850 | 0.302 | 0.334 | 3/4 - 16 | 0.7094 | 0.351 | 0.373 | -- -- | -- | -- | -- |

| 7/8 - 9 | 0.8028 | 0.419 | 0.462 | 7/8 - 14 | 0.8286 | 0.180 | 0.509 | -- -- | -- | -- | -- |

| 1 - 8 | 0.9188 | 0.551 | 0.606 | 1 - 12 | 0.9459 | 0.625 | 0.663 | 1 - 8 | 0.9188 | 0.551 | 0.606 |

| 1-1/8 - 7 | 1.0322 | 0.693 | 0.763 | 1-1/8 - 12 | 1.0709 | 0.812 | 0.856 | 1-1/8 - 8 | 1.0438 | 0.728 | 0.790 |

| 1-1/4 - 7 | 1.1572 | 0.890 | 0.969 | 1-1/4 - 12 | 1.1959 | 1.024 | 1.073 | 1-1/4 - 8 | 1.1688 | 0.929 | 1.000 |

| 1-3/8 - 6 | 1.2667 | 1.054 | 1.155 | 1-3/8 - 12 | 1.3209 | 1.260 | 1.315 | 1-3/8 - 8 | 1.2938 | 1.155 | 1.233 |

| 1-1/2 - 6 | 1.3917 | 1.294 | 1.405 | 1-1/2 - 12 | 1.4459 | 1.521 | 1.581 | 1-1/2 - 8 | 1.4188 | 1.405 | 1.492 |

| -- -- | -- | -- | -- | -- -- | -- | -- | -- | 1-5/8 - 8 | 1.5438 | 1.68 | 1.78 |

| 1-3/4 - 5 | 1.6201 | 1.74 | 1.90 | -- -- | -- | -- | -- | 1-3/4 - 8 | 1.6688 | 1.98 | 2.08 |

| -- -- | -- | -- | -- | -- -- | -- | -- | -- | 1-7/8 - 8 | 1.7938 | 2.30 | 2.41 |

| 2 - 4-1/2 | 1.8557 | 2.30 | 2.50 | -- -- | -- | -- | -- | 2 - 8 | 1.9188 | 2.65 | 2.77 |

| 2-¼ - 4-½ | 2.1057 | 3.02 | 3.25 | -- -- | -- | -- | -- | 2-1/4 - 8 | 2.1688 | 3.42 | 3.56 |

| 2-1/2 - 4 | 2.3376 | 3.72 | 4.00 | -- -- | -- | -- | -- | 2-1/2 - 8 | 2.4188 | 4.29 | 4.44 |

| 2-3/4 - 4 | 2.5876 | 4.62 | 4.93 | -- -- | -- | -- | -- | 2-3/4 - 8 | 2.6688 | 5.26 | 5.43 |

| 3 - 4 | 2.8376 | 5.62 | 5.97 | -- -- | -- | -- | -- | 3 - 8 | 2.9188 | 6.32 | 6.51 |

| 3-1/4 - 4 | 3.0876 | 6.72 | 7.10 | -- -- | -- | -- | -- | 3-1/4 - 8 | 3.1688 | 7.49 | 7.69 |

| 3-1/2 - 4 | 3.3376 | 7.92 | 8.33 | -- -- | -- | -- | -- | 3-1/2 - 8 | 3.4188 | 8.75 | 8.96 |

| 3-3/4 - 4 | 3.5876 | 9.21 | 9.66 | -- -- | -- | -- | -- | 3-3/4 - 8 | 3.6688 | 10.11 | 10.34 |

| 4 - 4 | 3.8376 | 10.61 | 11.08 | -- -- | -- | -- | -- | 4 - 8 | 3.9188 | 11.57 | 11.81 |

Stainless Steel Mechanical Properties

Mechanical Properties |

Comparison of Indian / Prop. Grades with various International Standards | ||||||||||

| Grade | Tensile Strenght Mpa (Min.) | Yield Strength Mpa (Min.) | %Elongation (Min.) | Hardness BHN | Hardness RB | INDIA / IS Letter Symbol |

INDIA / IS Numerical Symbol (ISS) | UNS Designation | GERMANY / DIN Designation |

JAPAN / JIS | USSR / GOST |

| (Max) | (Max) | ||||||||||

| 301 | 515 | 205 | 40 | 217 | 95 | X10Cr17Ni7 | 301 | S30100 | X12CrNi177 | SUS301 | - |

| 304 | 515 | 205 | 40 | 201 | 92 | X04Cr19Ni9 | 304SI/ 304s2 |

S30400 | X5CrNi1810 | SUS304 | 08Ch18N10 |

| X04Cr19Ni10 | |||||||||||

| 304H | 515 | 205 | 40 | 201 | 92 | - | - | S30409 | - | - | - |

| 304L | 485 | 170 | 40 | 201 | 92 | - | - | S30403 | X2CrNi1911 | SUS304L | 03Ch18N11 |

| G-X2CrNiN189 | SCS19 | ||||||||||

| 304LN | 515 | 205 | 40 | 201 | 92 | - | - | S30453 | X2CrNiN1810 | SUS304LM | - |

| 309 | 515 | 205 | 40 | 217 | 92 | X15Cr24Ni13 | 309 | - | X15CrNiSi2012 | SUS309 | 20Ch20NS2 |

| 309S | 515 | 205 | 40 | 217 | 95 | - | - | S30908 | X7CrNi2314 | SUS309S | - |

| 310 | 515 | 205 | 40 | 217 | 95 | X20Cr25Ni20 | 310 | - | X15CrNiSi2520 | SUH310 | 20Ch25N20S2 |

| 310S | 515 | 205 | 40 | 217 | 95 | - | - | S31008 | X12CrNi2521 | SUS310S | 20Ch23N18 |

| 316 | 515 | 205 | 40 | 217 | 95 | X04Cr17Ni12Mo2 | 316 | S31600 | X5CrNiMo1722 | SUS316 | - |

| 316L | 485 | 170 | 40 | 217 | 95 | X02Cr17Ni12Mo2 | 316L | S31603 | X2CrNiMO18143 | SUS316L | 3Ch17N14M3 |

| SCS16 | 3Ch16N15M3 | ||||||||||

| 316LN | 515 | 205 | 40 | 217 | 95 | - | - | S31653 | X2CrNiMoN17133 | SUS316LN | - |

| 316TI | 515 | 205 | 35 | 217 | 95 | X04Cr17Ni12Mo2Ti | S31635 | 316TI | X6CrNiMoTi17122 | - | 10Ch17N13M2T |

| 317 | 515 | 205 | 40 | 217 | 95 | - | S31700 | - | X5CrNiMo17133 | SUS317 | - |

| 317L | 515 | 205 | 40 | 217 | 95 | - | S31703 | - | X2CrNiMo18164 | SUS317L | - |

| 317LN | 550 | 240 | 40 | 217 | 95 | - | S31753 | - | - | - | - |

| 321 | 515 | 205 | 40 | 217 | 95 | X04Cr18Ni10Ti | 321 | S32100 | X6CrNiTi1810 | SUS321 | 08Ch18N10T |

| 347 | 515 | 205 | 40 | 201 | 92 | X04Cr18Ni10Nb | 347 | S34700 | X6CrNiNb1810 | SUS347 | 08Ch18N12B |

| 409 | 380 | 205 | 20 | 179 | 88 | - | - | S40900 | X6CrTi12 | - | - |

| 409RC | 350 | 170 | 30 | 179 | 88 | - | - | - | - | - | - |

| 409M | 450 | 275 | 20 | 187 | 90 | - | - | - | - | - | - |

| 410 | 450 | 205 | 20 | 217 | 96 | X12Cr12 | 410 | S41000 | X10Cr13 | SUS410 | - |

| 410S | 415 | 205 | 22 | 183 | 89 | - | - | S41008 | - | - | - |

| 405 | 415 | 170 | 20 | 179 | 88 | X04Cr12 | 405 | S40500 | X6CrA13i | SUS405 | - |

| 430 | 415 | 205 | 22 | 183 | 89 | X07Cr17 | 430 | S43000 | X6Cr17 | SUS430 | - |

| 430TI | 360 | 175 | 27 | 179 | 88 | - | - | - | X6CrTi17 | SUS430LX | - |

| 436 | 450 | 240 | 22 | - | 89 | - | - | S43600 | - | - | - |

| 420 | 690 | - | 15 | 217 | 96 | X20Cr13 | 420S1 | S42000 | X20Cr13 | SUS420JI | - |

| X30Cr13 | 420S2 | ||||||||||

| X40Cr13 | 420S3 | ||||||||||

| JBS | - | - | - | - | - | - | - | - | - | - | - |

| JSL AUS (J1) | 550 | 205 | 40 | 217 | 95 | - | - | - | - | - | - |

| J3 | 600 | 250 | 40 | 217 | 95 | - | - | - | - | - | - |

| J4 | 700 | 350 | 40 | 217 | 95 | - | - | - | - | - | - |

Grade Equivalent Table

| AISI / ASTM | UNS | British | German | Swedish | Japanese | ||

| Type | No. | BS | Eu | W.No. | DIN | SS | JIS |

| 301 | S30100 | 301S21 | - | 1.431 | X 12 CrNi 17 7 | 2331 | SUS 301 |

| 302 | S30200 | 302S25 | 58A | 1.43 | X 12 CrNi 18 8 | 2346 | SUS 302 |

| 303 | S30300 | 303S21 | 58M | 1.4305 | X 12 CrNiS 18 8 | - | SUS 303 |

| 303 Sc | S30323 | 303S41 | 58M | - | - | 2332 | SUS 303Sc |

| 304 | S30400 | 304S15 | 58E | 1.4301 | X 5 CrNi 18 9 | 2352 | SUS 304 |

| 304 L | S30403 | 304S12 | - | 1.4306 | X 2 CrNi 18 9 | - | SUS 304L |

| 304 N | S30451 | - | - | - | - | - | SUS 304N1 |

| 302 HQ | S30430 | - | - | 1.4567 | - | - | SUS XM7 |

| 305 | S30500 | 305S19 | - | 1.4312 | - | - | SUS 305 |

| 309 S | S30908 | 309S24 | - | 1.4833 | X 7 CrNi 23 14 | - | SUS 309 S |

| 310 | S31000 | 310S24 | - | 1.4841 | X 12 CrNi 25 20 | - | SUS 310 |

| 310 S | S31008 | 310S16 | - | 1.4845 | X 12 CrNi 25 21 | 2361 | SUS 310 S |

| S31254 | - | - | - | - | 2378 | - | |

| 314 | S31400 | - | - | 1.4841 | X 15 CrNi 25 20 | - | - |

| 316 | S31600 | 316S16 | 58H,58J | 1.4401 | X 5 CrNiMo 18 10 | 2347 | SUS 316 |

| 316 L | S31603 | 316S12 | - | 1.4404 | X 2 CrNiMo 18 10 | 2348 | SUS 316 L |

| 316 N | S31651 | - | - | 1.4406 | X 2 CrNiMoN 18 12 | - | SUS 316 N |

| 316 TI | S31635 | 320S17 | - | 1.4571 | X 10 CrNiMoTi 18 10 | 2350 | - |

| 317 | S31700 | 317S16 | - | 1.4449 | X 5 CrNiMo 17 13 | - | SUS 317 |

| 317 L | S31703 | 317S12 | - | 1.4438 | X 2 CrNiMo 18 16 | 2367 | SUS 317 L |

| 321 | S32100 | 32S12 | 58B,58C | 1.4541 | X 10 CrNiTi 18 9 | 2337 | SUS 321 |

| 329 | S32900 | - | - | 1.446 | X 8 CrNiMo 27 5 | 2324 | SUS 329J1 |

| 347 | S34700 | 347S17 | 58F, 58G | 1.455 | X 10 CrNiNb 18 9 | 2338 | SUS 347 |

| 348 | S34800 | 347S18 | - | 1.4546 | X 5 CrNiNb 18 10 | - | - |

| 384 | S38400 | - | - | - | - | - | SUS 384 |

| 403 | S40300 | 403S17 | - | 1.4 | X 7 Cr 13< | - | SUS 403 |

| 405 | S40500 | 405S17 | - | 1.4002 | X 7 CrAl 13 | 2301 | SUS 405 |

| 409 | S40900 | 409S19 | - | 1.4512 | X 5 CrTi 12 | - | SUS 409 |

| 410 | S41000 | 410S21 | 56A | 1.4006 | X 10 Cr 13 | 2302 | SUS 410 |

| 416 | S41600 | 416S21 | 56AM | 1.4005 | X 12 CrS 13 | 2380 | SUS 416 |

| 416Se | S41623 | - | - | - | - | - | - |

| 420 | S42000 | 420S37 | 56C | 1.4021 | X 20 Cr 13 | 2303 | SUS 420J1 |

| 420F | S42020 | - | - | - | - | - | SUS 420F |

| 430 | S43000 | 430S17 | 60 | 1.4016 | X 8 Cr 17 | 2320 | SUS 430 |

| 430F | S43020 | - | - | 1.4104 | X 12 CrMoS 17 | 2383 | SUS 430F |

| 431 | S43100 | 431S29 | 57 | 1.4057 | X 22 CrNi 17 | 2321 | SUS 431 |

| 434 | S43400 | 434S17 | - | 1.4113 | X 6 CrMo 17 | - | SUS 434 |

| 440C | S44044 | - | - | 1.4125; | X 105 CrMo 17 | - | SUS 440C |

| 444 | S44400 | - | - | 1.4521 | X 2 CrMoTi 18 2 | 2326 | SUS 444 |

| 630 | S17400 | - | - | 1.4542 | X 5 CrNiCuNb 17 4 | - | SUS 630 |

| 631 | S17700 | - | - | 1.4568 | X 7 CrNiAl 17 7 | 2388 | SUS 631 |

| + | N08904 | 904S13 | - | 1.4539 | X 1 NiCrMoCuN 25 20 5 | 2562 | - |

| + | S30815 | - | - | 1.4893 | - | 2377 | - |

| + | S31803 | - | - | 1.4462 | X 2 CrNiMoN 22 5 | 2327 | - |

| + | S32304 | - | - | 1.4362 | - | 2328 | - |

| + | S32750 | - | - | - | X 2 CrNiMoN 25 7 4 | - | - |

| + | S34565 | - | - | 1.4565 | X 2 CrNiMnMoN 24 17 6 4 | - | - |

| + | S32760 | - | - | 1.4501 | X 2 CrNiMoCuWN 25 7 4 | - | - |

Typical Application

| Grade | Characteristics | Typical Applications |

|---|---|---|

| 304L | Low Carbon level (0.03 max.) | Used for parts and structures which can |

| Austenitic | Improved resistance to | not be heat treated for stress relieving |

| intergranular corrosion. | after welding less tendency to work | |

| hardening. | ||

| 310S | High Creep strength and | look heaters annealing boxes |

| Austenitic | mechanical properties at | Ovens |

| higher temperature | Carburising boxes | |

| Fire box sheets | ||

| Furnace lining | ||

| Furnace stacks, and dampers | ||

| Gas turbine parts | ||

| Heat exchangers | ||

| Kiln lining | ||

| Nozzle diaphragm assemblies for turbo jet engines | ||

| Oil burner parts | ||

| Paper mill equipment | ||

| Oil refinery equipment | ||

| Recuperators | ||

| 316L | Reduced tendency towards | For parts which cannot be heat treated |

| Austenitic | carbide precipitation. | after welding. |

| 304 | Excellent corrosion | Chemical, petrochemical and fertiliser industries and as an equipment in dairy |

| Austenetic | resistance & forming | Food processing |

| characteristics. | Pharmaceutical Industries | |

| Hospitals | ||

| Households as Kitchenware | ||

| Cryogenic | ||

| Vessels | ||

| Heat exchangers in Air conditioning | ||

| Refrigerator, | ||

| For machinery in paper, pulp, textile, beverage sector | ||

| Architectural applications as panels, curtain walls, roofing | ||

| 301 | Able to attain high strength | Automobile items |

| Austenetic | and ductility through | Conveyer belts |

| moderate or severe Cold | Railway Coaches | |

| Working. | Metal Fixtures for construction purposes | |

| Roof drainage products | ||

| Door frames tableware etc | ||

| 316 | 2-3% Mo which improves | Architectural items |

| Austenitic | Austenitic corrosion | Marine exteriors |

| resistance to halogens and | Chemical processing equipment | |

| imports hot strength | Food processing equipment | |

| characteristics resistance to | Petroleum refining equipment | |

| pitting corrosion. | Pharmaceutical equipments | |

| Photographic equipment | ||

| Pulp and paper processing equipment | ||

| textile finishing equipment | ||

| 321 Austenitic | Similar to 304 but stabilised | Air craft exhausts |

| with Titanium to avoid | Stacks and manifolds | |

| intergranular corrosion. | Pressure vessels | |

| Resists sealing and vibration | Large mufflers for stationary diesel engines | |

| fatigue. | Carburetors | |

| Expansion bellows | ||

| Stack liners | ||

| Thin wall tubes |

Tubes, Pipes, Cutlery, Utensils, Automobile parts, Kitchen Sinks, LPG Gas Stoves, Electronic Components, Furniture, Decorative Applications, Structural fabrications and other similar applications.

Typical Application

Due to their good formability, weldability and corrosion resistance, Stainless 200 series grades can be used for applications as detailed below :-

| Catering & Food Processing | |

| JSL AUS(J1) | Deep drawn utensils, pressure cookers, water filters, storage vessels, milk, kitchen sinks etc. |

| J204Cu, J4 | Shallow/medium drawn utensils, tablewares, cutlery, stand for water filters, flasks, dog pots |

| Consumer Durables | |

| JSL AUS(J1) | White goods/house hold appliances, washing machines, microwaves ovens, thermo-ware |

| J204Cu, J4 | White goods dry applications, steel furniture, decorative tubing |

| Architecture, Building & Construction | |

| JSL AUS(J1) | Outdoor non-coastal |

| J204Cu, J4 | Indoor decorative, handrails, ornamental tubes, doors & window frames,door hinges/knobs, street furniture, tree guards, dustbin |

| Transport (Automotive) | |

| JSL AUS(J1) | Automotive trim, wheel caps, wiper arms, auto accessories, motorcycle rims |

| J204Cu, J4 | Interior decorative accessories, structurals, bus body, rail car |

Formula Of Weight

| 1 | Weight of Stainless Steel Pipes & Tubes | OD(mm)-W.T. (mm) x W.T.(mm)x0.02466=Kg.per Mtr |

| 2 | Sheet Width Required for rolled and welded pipes | O.D.(mm) - THK(mm) x 3.14=SheetWidth |

| 3 | Weight of Stainless Steel Sheets | Length (mtr.) x Wdth(mtr.) x Thk(mm)x8=Kg Per Sheet |

| 4 | Weight of Stainless Steel Circle & Blanks | OD(mm) x OD>(mm) x Thk(mm)/160/1000=Kg Per Pcs |

| 5 | Weight of Stainless Steel Rounds | Dia.(mm)xdia.(mm) x 0.00623=PerMtr |

| 6 | Weight of Stainless Steel Hexagonal Rods | Dia.(mm)xDia.(mm) x 0.00679=PerMtr |

| 7 | Weight of stainless Steel Square Bars | Dia.(mm)xDia.(mm) x 0.00787=PerMtr |

| 8 | Weight of Aluminium Pipes(appro.) | OD(mm)-W.T. (mm) XW.T.(mm) x 0.0082=Kg per Mtr. |

| 9 | Weight of Aluminium Sheets(appro.) | Length (mtr.) X Width(mtr.) X Thk(mm) x 2.66=Kg Per Sheet |

Weight Of S.S. Pipe

WEIGHT OF S.S.PIPE

Weight of stainless steel pipe per running feet.

| Inch. | o.d. | 10 swg. | 12 swg. | 14 swg | 16 swg | 18 swg | 20swg | 22 swg |

|---|---|---|---|---|---|---|---|---|

| ¼’’ | 6.4 | …. | …. | 6.6 | .58. | 0.47 | 0.37 | .30 kgs. |

| 3/8’’ | 9.5 | 0.153 | 0.137 | 0.114 | 0.97 | 0.76 | 0.59 | .47 kgs. |

| ½’’ | 12.7 | 0.231 | 0.199 | 0.163 | 0.135 | 0.105 | 0.81 | .64 kgs. |

| 5/8’’ | 15.9 | 0.308 | 0.263 | 0.211 | 0.174 | 0.134 | 0.103 | .81 kgs. |

| ¾’’ | 19.1 | 0.386 | 0.326 | 0.26 | 0.213 | 0.163 | 0.125 | .98 kgs. |

| 7/8’’ | 22.2 | 0.463 | 0.388 | 0.305 | 0.251 | 0.192 | 0.147 | .115kgs. |

| 1’’ | 25.4 | 0.54 | 0.452 | 0.357 | 0.29 | 0.221 | 0.168 | .132kgs. |

| 1 ¼’’ | 28.6 | 0.618 | 0.514 | 0.405 | 0.329 | 0.25 | 0.19 | .149kgs. |

| 1 ½’’ | 38.1 | 0.851 | 0.704 | 0.55 | 0.445 | 0.388 | 0.255 | .199kgs. |

| 1 ¼’’ | 31.7 | 0.676 | 0.577 | 0.454 | 0.368 | 0.276 | 0.212 | .166kgs. |

| 1 ¾’’ | 44.4 | 1.006 | 0.829 | 0.677 | 0.523 | 0.396 | 0.299 | ….kgs. |

| 2’’ | 50 | 1.161 | 0.953 | 0.744 | 0.6 | 0.454 | 0.343 | ….kgs. |

| 2 ¼’’ | 57.1 | 1.316 | 1.081 | 0.841 | 0.678 | 0.512 | 0.386 | ….kgs. |

| 2 ½’’ | 63.5 | 1.471 | 1.207 | 0.938 | 0.755 | 0.57 | 0.43 | ….kgs. |

| 3’’ | 76.2 | 1.781 | 1.459 | 1.132 | 0.91 | 0.686 | 0.517 | …kgs. |

| 3 ¼’’ | 82.5 | 1.936 | 1.585 | 1.229 | 0.988 | 0.744 | …. | ….kgs. |

| 3 ½’’ | 88.3 | 2.091 | 1.711 | 1.326 | 1.066 | 0.823 | …. | ….kgs. |

| 4’’ | 101.6 | 2.401 | 1.963 | 1.519 | 1.22 | 0.919 | …. | …kgs. |

| 4 ¼’’ | 108 | 2.556 | 2.088 | 1.612 | 1.298 | …. | …. | ….kgs. |

| 4 ½’’ | 114.3 | 2.711 | 2.215 | 1.713 | 1.375 | …. | …. | ….kgs. |

| 5’’ | 127 | 3.021 | 2.467 | 1.907 | …. | …. | …. | ….kgs. |

| 5 ½’’ | 139.7 | 3.381 | 2.781 | …. | …. | …. | …. | ….kgs. |

| 6’’ | 15.24 | 3.642 | …. | …. | …. | …. | …. | ….kgs. |

| 6 ½’’ | 165.1 | 3.952 | …. | …. | …. | …. | …. | ….kgs. |

| 8'” | 203.2 | 4.883 | …. | …. | …. | …. | …. | ….kgs. |

| O.D. - Thickness X Thickness X .700756 = 1 Foot Weight | ||||||||

Non Ferrous Metal

| U.S.A. / GROSSBRITAINNIE U.S.A. / GRANDE-BRETAGNE U.S.A. / GREAT BRITAIN | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Analysis Composition | |||||||||||||

| Handels bezeichung |

C% | Co% | Cr% | Mo% | Ni% | V% | W% | Ai% | Cu% | Nb/Cb Ta% | Ti% | Fe% | Sonstige Autres-Other% |

| Designation Commercial | |||||||||||||

| Commercial designation | |||||||||||||

| Monel 400 | 0.12 | - | - | - | 65 | - | - | - | 32 | - | - | 1.5 | Mn 1.0 |

| Monel 401 | 0.1 | - | - | - | 43 | - | - | - | 53 | - | - | 0.75 | Si 0.25; Mn 2.25 |

| Monel 404 | 0.15 | - | 52.0-57.0 | - | - | 0.05 | rest/bal | - | - | 0.5 | Mn 0.10; Si 0.10;S o.024 | ||

| Monel 502 | 0.1 | - | - | - | 63.0-17.0 | - | - | 2.5-3.5 | rest/bal | - | 0.5 | 2 | Mn 1.5;Si 0.5; S 0.010 |

| Monel K 500 | 0.13 | - | - | - | 64 | - | - | 2.8 | 30 | - | 0.6 | 1 | Mn 0.8 |

| Monel R 405 | 0.15 | - | - | - | 66 | - | - | - | 31 | - | - | 1.2 | Mn 1.0; S 0.04 |

| Hastelloy B | 0.1 | 1.25 | 0.6 | 28 | rest/bal | 0.3 | - | - | - | - | - | 5.5 | Mn 0.80; Si 0.70 |

| Hastelloy B2 | 0.02 | 1 | 1 | 26.0-30.0 | rest/bal | - | - | - | - | - | - | 2 | Mn 1.0: Si 0.10 |

| Hastelloy C | 0.07 | 1.25 | 16 | 17 | rest/bal | 0.3 | 40 | - | - | - | - | 5.75 | Mn 1.0 :Si 0 0.70 |

| Hastelloy C4 | 0.015 | 2 | 14.0-18.0 | 14.0-17.0 | rest/bal | - | - | - | - | - | 0..70 | 3 | Mn 1.0 ; Si 0.08 |

| Hastelloy C 276 | 0.02 | 2.5 | 14.0-16.5 | 15.0-17.0 | rest/bal | 0.35 | 3.0-4.5 | - | - | - | - | 4.0-7.0 | Mn 1.0;Si 0.05 |

| Hastelloy F | 0.02 | 1.25 | 22 | 6.5 | rest/bal | - | 0.5 | - | - | Nb2.10 | - | 21 | Mn 1.50;Si 0.50 |

| Hastelloy G | 0.05 | 2.5 | 21.0-23.5 | 5.5-7.5 | rest/bal | - | 1 | - | 1.5-2.5 | Nb1.75-2.5 | - | 18.0-21.0 | Mn 1.0-2.0;p0.04;Si 1.0;80.03 |

| Hastelloy G-2 | 0.03 | - | 23.0-26.0 | 5.0-7.0 | 47.0-52.0 | - | - | - | 0.70-1.20 | - | 0.70-1.50 | rest/bal | Mn 1.0;Si 1.0 |

| Hastelloy N | 0.06 | 0.25 | 7 | 16.5 | rest/bal | - | 0.2 | - | 0.1 | - | - | 3 | Mn 0.40;Si 0.25;B0.01 |

| Hastelloy S | 0.02 | 2 | 15.5 | 14.5 | rest/bal | 0.6 | 1 | 0.2 | - | - | - | 3 | Mn 0.50;Si 0.40;B0.0009;LA 0.02 |

| Hastelloy W | 0.06 | 1.25 | 5 | 24.5 | rest/bal | - | - | - | - | - | - | 5.5 | Mn 0.050 ; Si 0.50 |

| Hastelloy X | 0.1 | 1.5 | 22 | 9 | rest/bal | - | 0.6 | - | - | - | 18.5 | - | Mn 0.6; Si 0.60 |

| Incoloy 800 | 0.04 | - | 21 | - | 32 | - | - | 0.3 | - | - | 0.4 | 45 | - |

| Incoloy 800 H | 0.08 | - | 21 | - | 32 | - | - | 0.3 | - | - | 0.4 | 45 | - |

| Incoloy 801 | 0.05 | - | 20.5 | - | 32 | - | - | - | - | - | 1.1 | 45 | - |

| Incoloy 802 | 0.35 | - | 21 | - | 32 | - | - | 0.6 | - | - | 0.7 | 45 | - |

| Incoloy 804 | 0.05 | - | 29.5 | - | 41 | - | - | 0.3 | - | - | 0.6 | 25.4 | - |

| Incoloy 805 | 0.12 | - | 7.5 | 0.5 | 36 | - | - | - | 0.1 | - | - | rest/bal | Mn 0.60;Si 0.50 |

| Incoloy 810 | 0.25 | - | 21 | - | 32 | - | - | - | 0.5 | - | - | rest/bal | Mn 0.90; Si 0.80 |

| Incoloy 825 | 0.04 | - | 21 | 3 | 42 | - | - | - | 2 | - | 1 | 30 | - |

| Incoloy 825 Cp | 0.04 | - | 21.5 | 3 | 42 | - | - | - | 2.2 | Nb0.9 | - | 30 | - |

| Incoloy 840 | 0.08 | - | 20 | - | 20 | - | - | - | - | - | - | rest/bal | Mn 1.0;Si 1.0 |

| Incoloy 901 | 0.05 | - | 12.5 | 6 | rest/bal | - | - | 0.15 | - | - | 2.7 | 34 | Mn 0.24;Si 0.12;B0.015 |

| Incoloy 901 Mod | 0.05 | - | 12.5 | 5.8 | rest/bal | - | - | - | - | - | 2.9 | 34 | Mn 0.09;Si 0.08;B0.015 |

| Incoloy 903 | 0.02 | 15 | - | - | 38 | - | - | 0.7 | - | Nb 3.0 | 1.4 | 41 | - |

| Incoloy 904 | 0.02 | 14 | - | - | 33 | - | - | - | - | - | 1.7 | 50 | - |

| Incoloy DS | 0.06 | - | 18 | - | 37 | - | - | - | - | - | - | 42 | Mn 1.0; Si 2.3 |

| Incoloy Ma 956 | - | - | 20 | - | - | - | - | 4.5 | - | - | 0.5 | 74.4 | Y2.03 0.5 |

| Incoloy 600 | 0.05 | - | 15.5 | - | 75 | - | - | - | - | - | - | 8 | - |

| Incoloy 601 | 0.05 | - | 23 | - | 60 | - | - | 1.4 | - | - | - | 14 | - |

| Incoloy 604 | 0.04 | - | 15.8 | - | rest/bal | - | - | - | 0.1 | Nb 2.0 | - | 7.2 | Mn 0.20; Si 0.20 |

| Incoloy 610 | 0.2 | - | 15.5 | - | rest/bal | - | - | - | 0.5 | Nb 1.0 | - | 9 | Mn 0.90;Si 2.0 |

| Incoloy 617 | 0.07 | 12.5 | 22.5 | 9 | 54 | - | - | 1 | - | - | - | - | - |

| Incoloy 625 | 0.05 | - | 21.5 | 9 | 61 | - | - | 0.4 | - | Nb 3.65 | 0.4 | 2.5 | Mn 0.50; Si 0.50 |

| Incoloy 671 | 0.05 | - | 48 | - | 51 | - | - | - | - | - | 0.35 | - | - |

| Incoloy 700 | 0.12 | 28.5 | 15 | 3.75 | 46 | - | - | 3 | 0.05 | - | 2.2 | 0.7 | Mn 0.10; Si 0.30 |

| Incoloy 702 | 0.04 | - | 15.6 | - | rest/bal | - | - | 3.4 | 0.1 | - | 0.7 | 0.35 | Mn 0.05: Si 0.20 |

| Incoloy 705 | 0.3 | - | 15.5 | - | rest/bal | - | - | - | 0.5 | - | - | 8 | Mn 0.90 ; Si 5.5 |

Line Pipe Weight

| Nominal Pipe Size | Outside Diameter | Sch *5 |

Sch *10 |

Schedule 20 |

Schedule 30 |

Standard weig ht |

Schedule 40 |

Extra Strong | Schedule 60 |

Schedule 80 |

schedule 100 |

Schedule 120 |

Schedule 140 |

Schedule 160 |

Double Ex.Str. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m |

| 8 | 1/4 | 13.7 | -- | 0.491 | -- | -- | 0.63 | 0.63 | 0.80 | -- | 0.80 | -- | -- | -- | -- | -- |

| 10 | 3/8 | 17.1 | -- | 0.631 | -- | -- | 0.84 | 0.84 | 1.10 | -- | 1.10 | -- | -- | -- | -- | -- |

| 15 | 1/2 | 21.3 | 0.801 | 0.999 | -- | -- | 1.27 | 1.27 | 1.62 | -- | 1.62 | -- | -- | -- | 1.95 | 2.55 |

| 20 | 3/4 | 26.7 | 1.020 | 1.280 | -- | -- | 1.69 | 1.69 | 2.19 | -- | 2.19 | -- | -- | -- | 2.90 | 3.63 |

| 25 | 1 | 33.4 | 1.290 | 2.090 | -- | -- | 2.50 | 2.50 | 3.23 | -- | 3.23 | -- | -- | -- | 4.23 | 5.45 |

| 32 | 11/4 | 42.2 | 1.650 | 2.69 | -- | -- | 3.38 | 3.38 | 4.47 | -- | 4.47 | -- | -- | -- | 5.60 | 7.76 |

| 40 | 11/2 | 48.3 | 1.900 | 3.11 | -- | -- | 4.05 | 4.05 | 5.41 | -- | 5.41 | -- | -- | -- | 7.24 | 9.55 |

| 50 | 2 | 60.3 | 3.340 | 3.92 | -- | -- | 5.44 | 5.44 | 7.48 | -- | 7.48 | -- | -- | -- | 11.11 | 13.45 |

| 65 | 21/2 | 73.0 | 3.690 | 5.26 | -- | -- | 8.62 | 8.62 | 11.41 | -- | 11.41 | -- | -- | -- | 14.91 | 20.39 |

| 80 | 3 | 88.9 | 4.510 | 6.45 | -- | -- | 11.29 | 11.29 | 15.27 | -- | 15.27 | -- | -- | -- | 21.33 | 27.67 |

| 90 | 31/2 | 101.6 | 5.180 | 7.41 | -- | -- | 13.57 | 13.57 | 18.63 | -- | 18.63 | -- | -- | -- | -- | -- |

| 100 | 4 | 114.3 | 5.940 | 8.38 | -- | -- | 16.07 | 16.07 | 22.31 | -- | 22.31 | -- | 28.30 | -- | 33.53 | 41.02 |

| 125 | 5 | 141.3 | 9.340 | 11.60 | -- | -- | 21.78 | 21.78 | 30.95 | -- | 30.95 | -- | 40.28 | -- | 49.09 | 57.42 |

| 150 | 6 | 168.3 | 11.30 | 13.80 | -- | -- | 28.26 | 28.26 | 42.56 | -- | 42.56 | -- | 54.20 | -- | 67.55 | 79.18 |

| 200 | 8 | 219.1 | 14.80 | 20.00 | 33.31 | 36.79 | 42.53 | 42.53 | 64.63 | 53.09 | 64.63 | 75.89 | 90.43 | 100.93 | 111.25 | 107.87 |

| 350 | 10 | 273.1 | 22.60 | 27.80 | 41.77 | 51.00 | 60.29 | 60.29 | 81.55 | 81.54 | 95.97 | 114.70 | 133.00 | 155.10 | 172.25 | 155.10 |

| 300 | 12 | 323.9 | 31.24 | 35.99 | 49.72 | 65.20 | 73.82 | 79.72 | 97.44 | 108.96 | 132.01 | 159.85 | 186.92 | 208.04 | 238.72 | 186.92 |

| 350 | 14 | 355.6 | 34.34 | 54.68 | 67.94 | 81.28 | 81.28 | 94.49 | 107.38 | 126.68 | 158.08 | 194.90 | 224.60 | 253.53 | 281.68 | -- |

| 400 | 16 | 406.4 | 41.56 | 62.63 | 77.86 | 93.21 | 93.21 | 123.29 | 123.29 | 160.12 | 203.48 | 245.50 | 286.62 | 333.11 | 365.39 | -- |

| 450 | 18 | 457 | 46.80 | 70.59 | 87.79 | 122.36 | 105.14 | 155.91 | 139.19 | 205.80 | 254.59 | 309.76 | 363.65 | 408.45 | 459.51 | -- |

| 500 | 20 | 508 | 59.32 | 78.84 | 177.07 | 155.10 | 117.07 | 183.37 | 155.01 | 247.85 | ||||||

| 550 | 22 | 559 | 65.30 | 86.50 | 129.01 | 171.01 | 129.01 | -- | 171.01 | -- | ||||||

| 600 | 24 | 610 | 82.52 | 94.45 | 140.94 | 209.54 | 140.94 | 255.14 | 186.92 | 355.02 | ||||||

| 650 | 26 | 660 | -- | 127.50 | 202.83 | -- | 152.87 | -- | 202.83 | -- | ||||||

| 700 | 28 | 711 | -- | 137.42 | 218.73 | 272.18 | 164.80 | -- | 218.73 | -- | ||||||

| 750 | 30 | 762 | 118.33 | 147.36 | 234.64 | 292.06 | 176.73 | -- | 236.64 | -- | ||||||

| 800 | 32 | 813 | -- | 152.28 | 250.55 | 311.95 | 188.66 | 342.70 | 250.55 | -- | ||||||

| 850 | 34 | 864 | -- | 167.20 | 266.46 | 331.83 | 200.59 | 364.58 | 266.46 | -- | ||||||

| 900 | 36 | 914 | -- | 177.13 | 282.36 | 351.72 | 212.52 | 420.52 | 282.36 | -- | ||||||